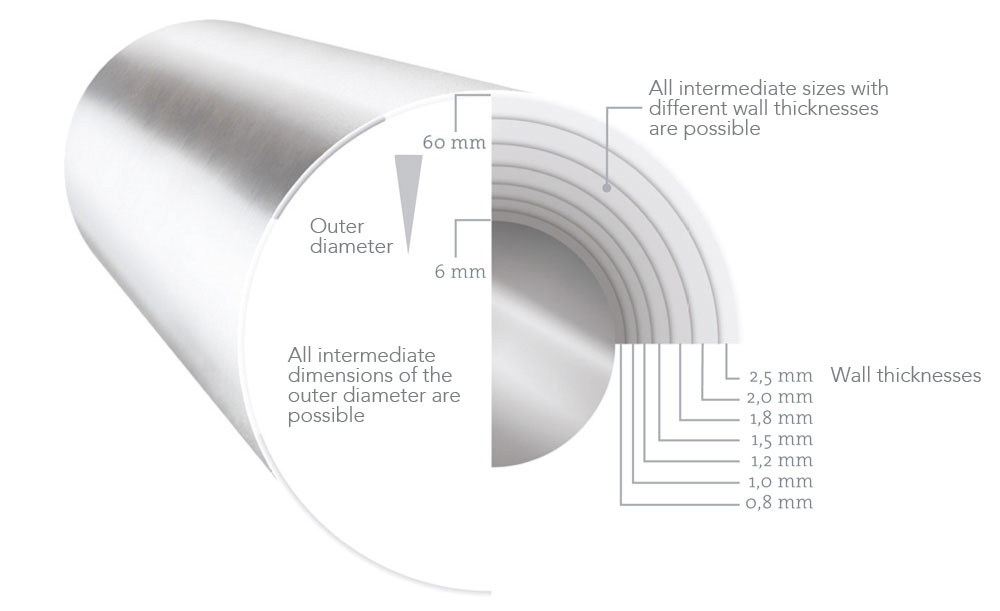

MESU produces longitudinally welded precision steel tubes according to DIN EN 10305-3 and DIN EN 10305-5. These are characterised, in particular, by tight tolerances and a uniform surface quality. In addition to material used in standard grades such as DC01, E235 or E355 hot and cold strip, we also process high-strength and ultra high-strength steels such as dual-phase steel. Tubes are delivered in the states +CR1, +CR2, +N and +A depending on their respective purpose of use. MESU’s quality in terms of systems and processes complies with the requirements of the IATF 16949 certification issued by TÜV Nord. The certificate according to IATF 16949 documents our quality capability as a partner and supplier to the automobile industry.

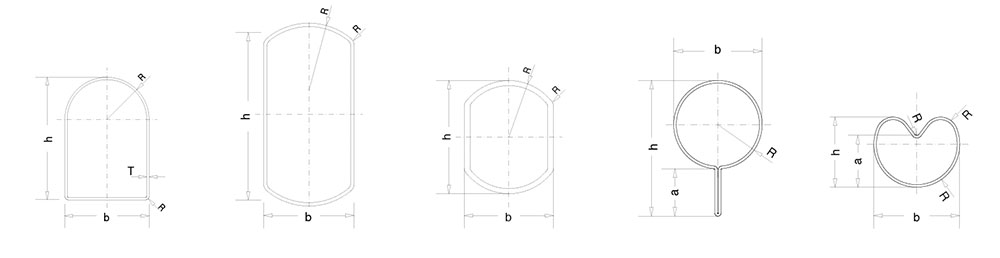

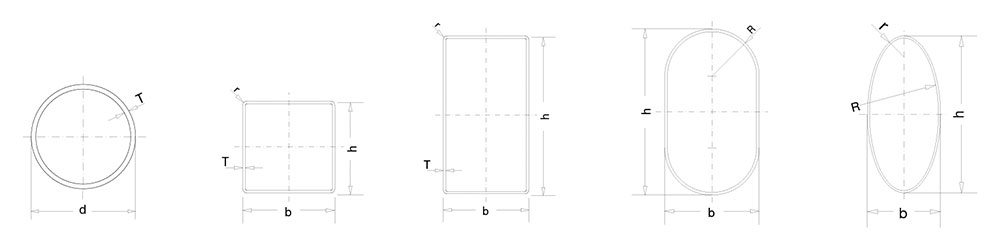

Our product range includes round tubes, square tubes, rectangular tubes, flat semi-circular tubes, elliptical oval tubes, as well as tailor-made products for various branches of industry (special profiles).

The specification of the parts to be joined like dimension, weight and material, type of welded joint etc. is the basis for the selection of the welding process.

Further processing occurs in our in-house furnace at temperatures of up to 930 degrees Celsius under an inert gas atmosphere if necessary and in accordance with the required material properties.

Depending on the production demands, various saw advisory centres, saw machining centres and tube saws are available, and where, upon request, deburring, washing and drying can be carried out easily on the saws.

We offer the following surface treatments in conjunction with our partners:

Round tubes, square tubes, rectangular tubes, flat semi-circular tubes, elliptical oval tubes

Tailor-made products for various branches of industry