We engage in the further processing of tubes according to customer requirements in our corporate division for tube technology. We are able to produce parts of different dimensions, shapes and finishing steps on a small or large-scale. The processing of different material grades such as stainless steel, aluminium, copper, brass, and carbon, etc. also belongs to our portfolio. With the variety of processing options available to us, we are completely geared toward our customers' markets. We provide security in the planning process, the most advanced production and processing systems and compliance with the required quality standards. Technical developments and changes in design are included in the planning and implementation from the onset.

Thanks to our many years of experience in the area of tube machining, and in combination with our extensive machinery, we are a competent partner for development. MESU allows creative freedom, an essential element for visionary work with the customer.

Standard dimensions

Tube machining services with tube diameters of 6-65mm, for all usage purposes in accordance with designs and data records, are standard for us. However, we can also carry out the service for dimensions outside the given dimensions. Please do not hesitate to contact us regarding this.

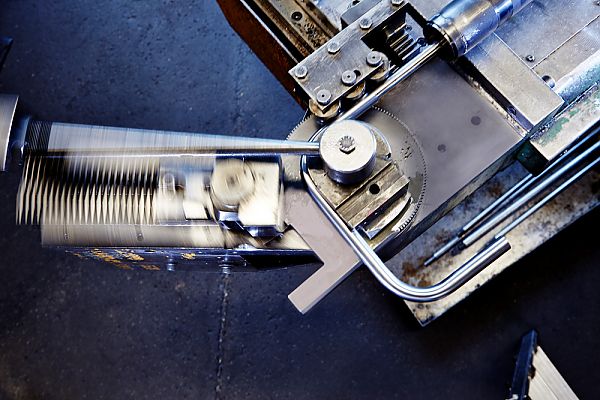

The tubes can first be cut from random lengths to fixed lengths using various sawing machines according to the customer’s specification with the help of cutting support centres. After the saw cut, further processing steps can be carried out, including deburring (inside and/or outside) by means of brush deburring, chip removal and degreasing of the tubes using washing processes.

Tubes and profiles made of the materials steel, stainless steel and aluminum are processed on our modern laser systems. In use are outside diameters or side lengths up to about 150 mm and wall thicknesses up to 5 mm.

We are glad to incorporate our experience with laser cutting technology into your products, because our laser cutting technology sets new standards for the design, development and processing of these products. The design of the pipes and profiles to be processed is just as important for the productivity and process capability of the lasered products.

Tube bending on semi and fully automatic CNC bending machines and bending presses with a machine park consisting of 15 tube processing machines according to individual design/customer specifications.

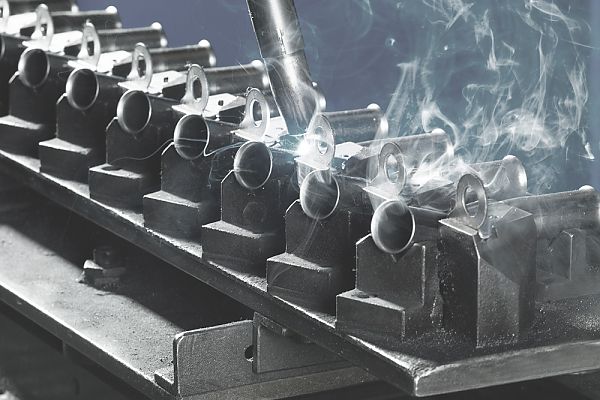

Final assembly of individual components to modules and/or semi-finished parts using various welding operations and procedures:

Surface treatment according to customer requirements such as: